Merlin Field Joint Heating & Coating

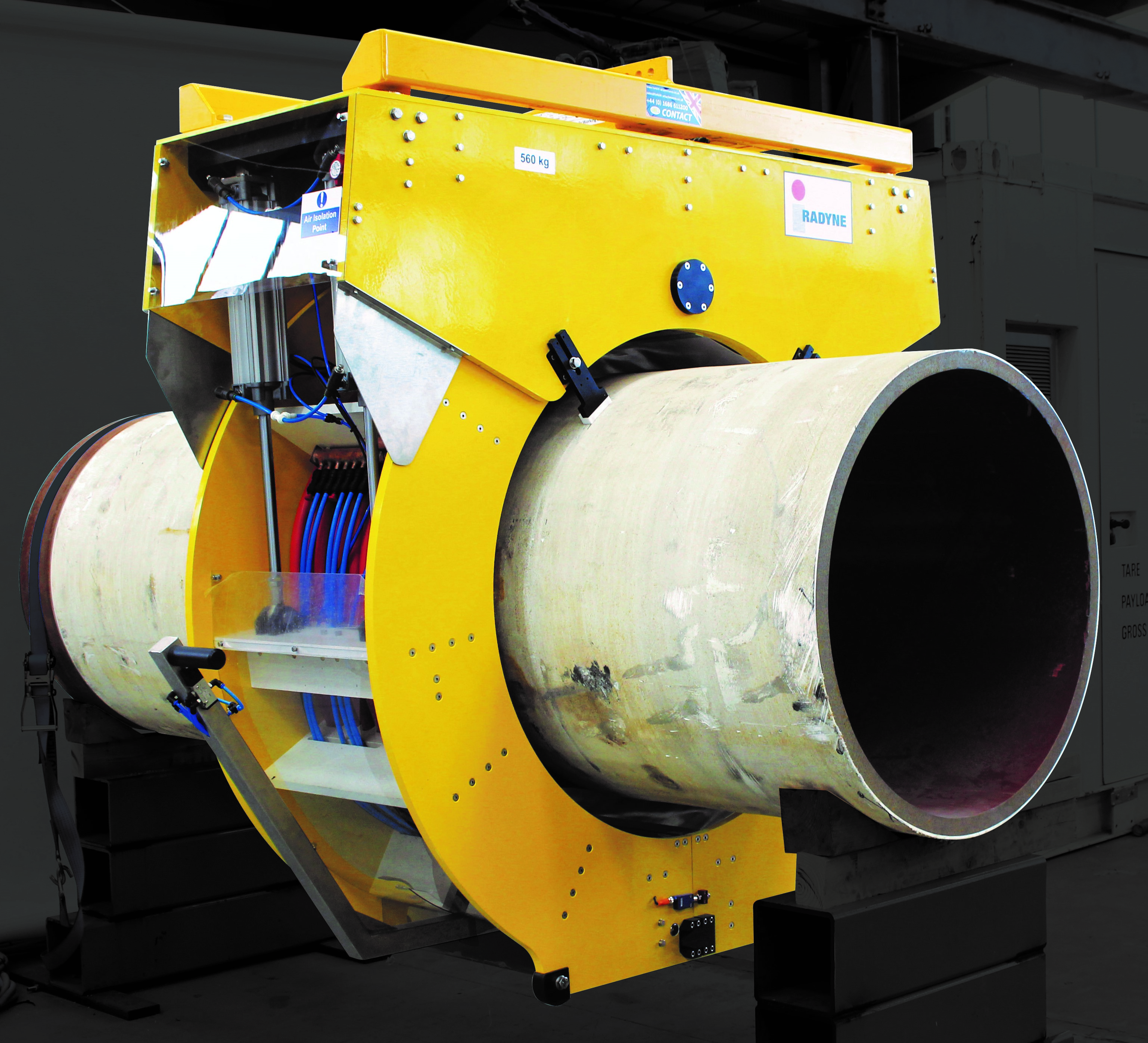

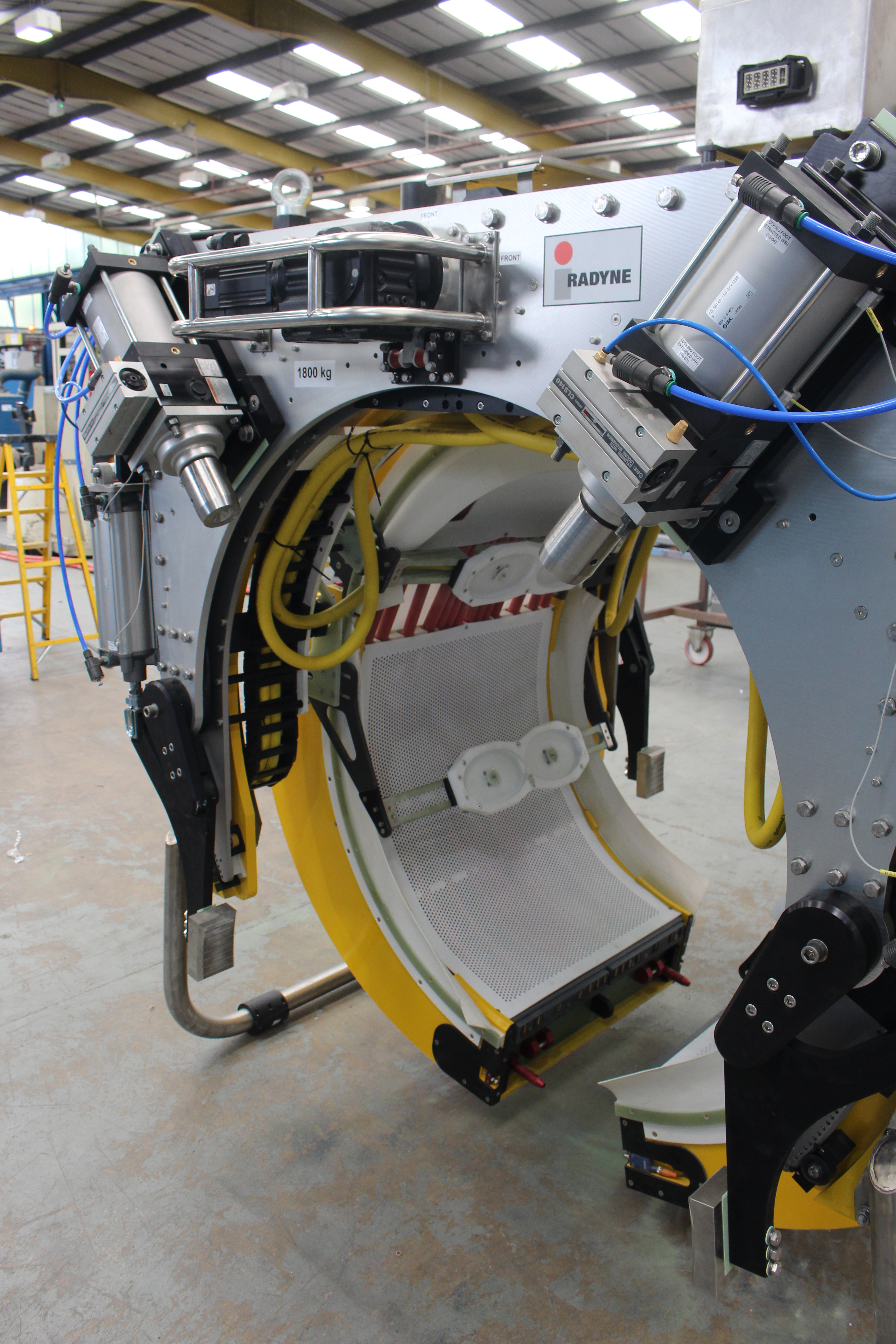

Radyne Merlin™ systems use patented technology to deliver the most efficient means of heating and coating field joints by carrying out both operations simultaneously within a single machine. This is a major benefit to offshore pipe laying operations as the Radyne Merlin™ provides reduced field joint heating and coating cycle times, allowing faster throughput of field joints prior to laying.

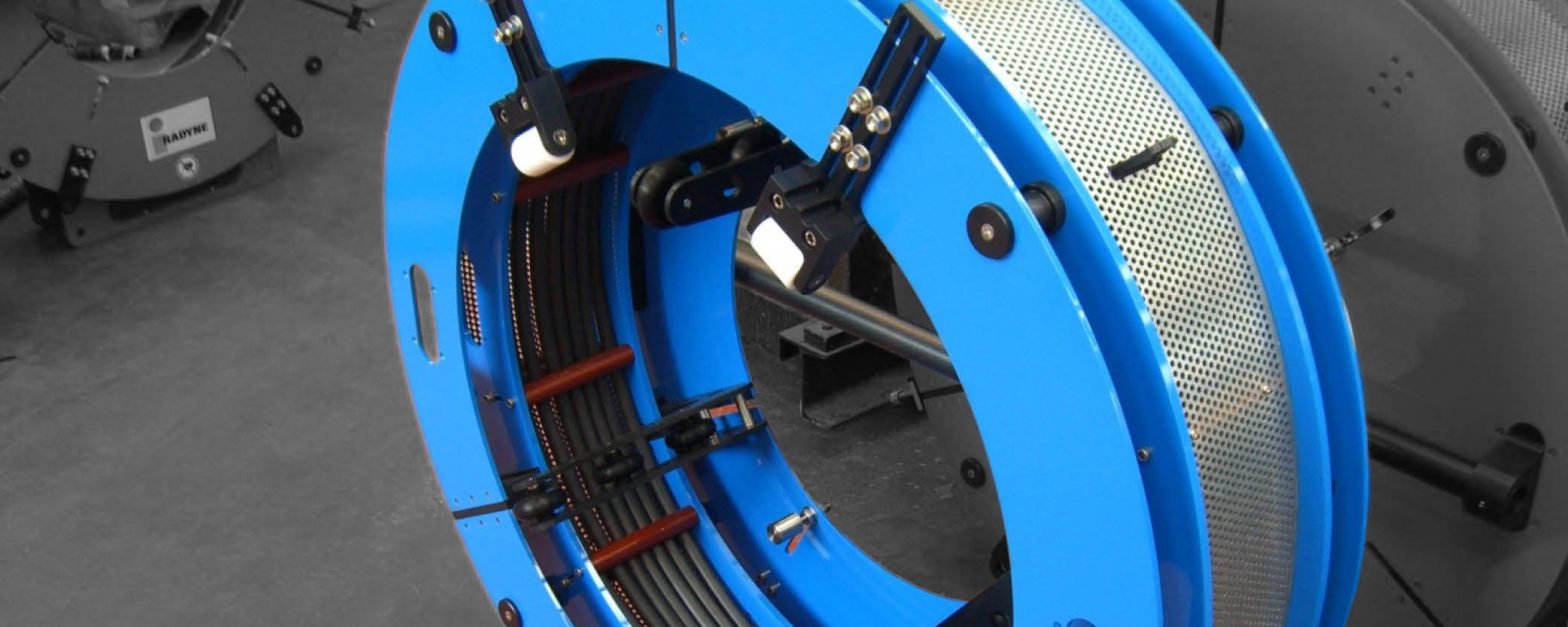

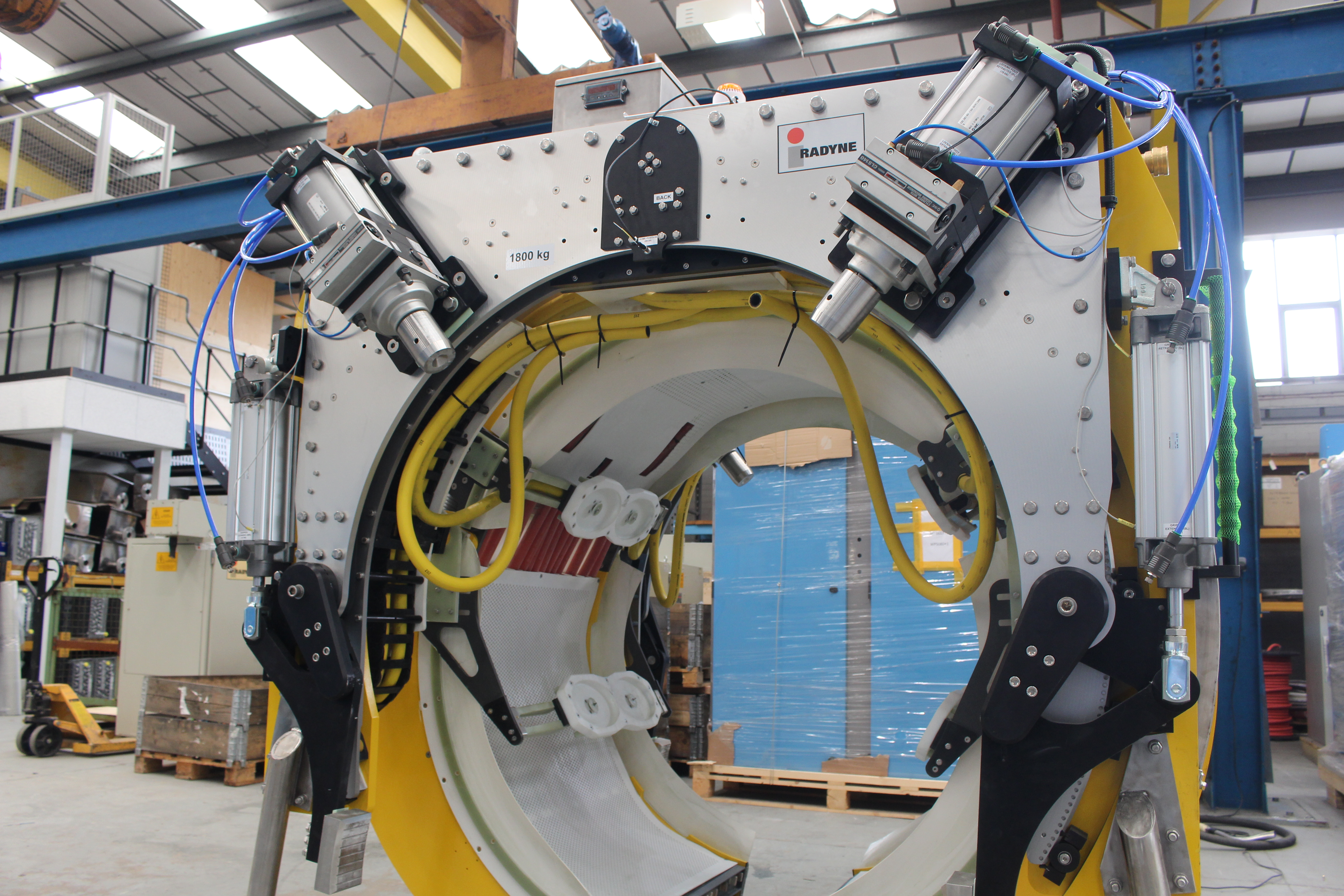

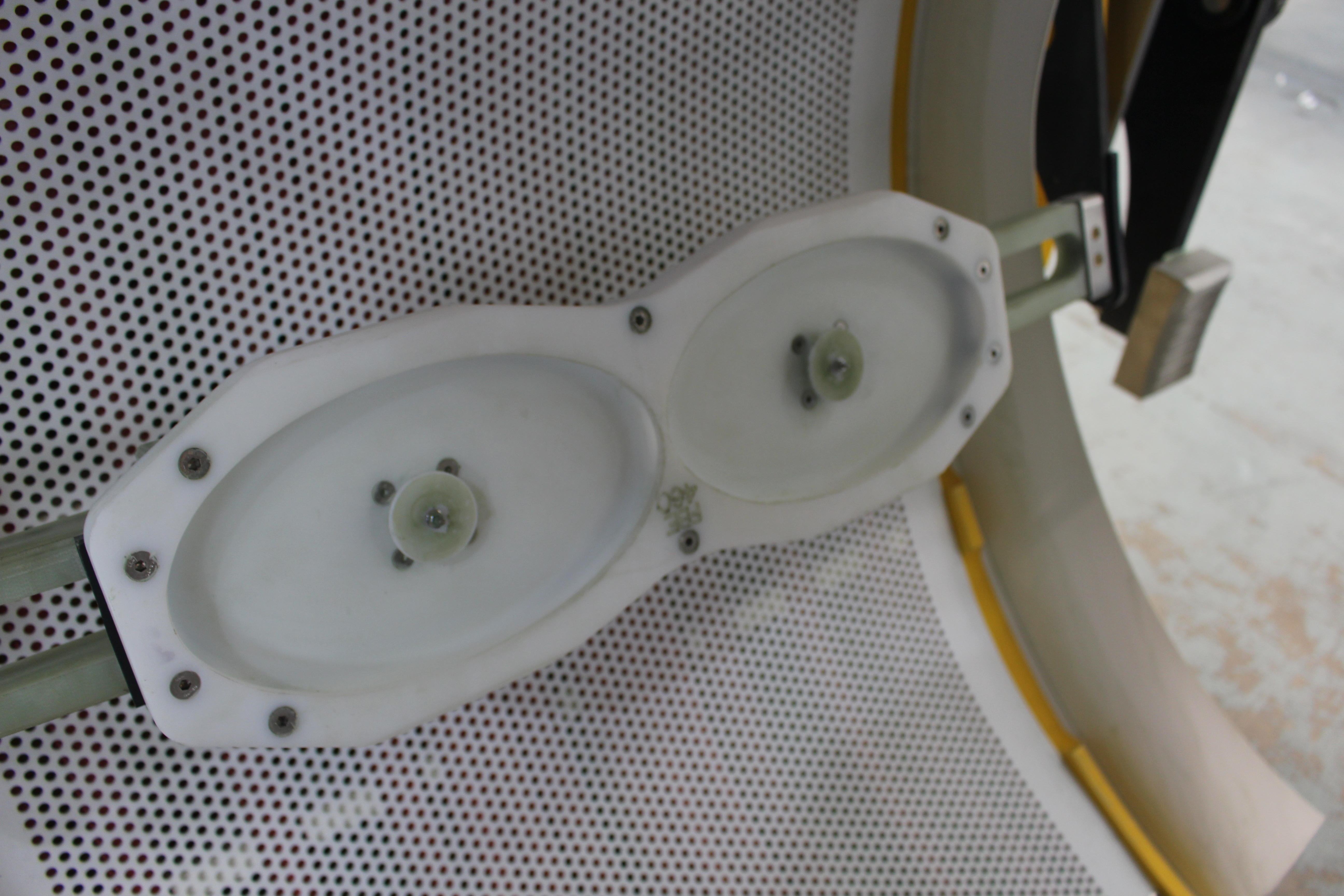

Our system combines integrated induction coils and coating heads for a fully automated heat and coat process. This allows for the precision application of a two-coat FBE and co-polymer anti corrosion coating.

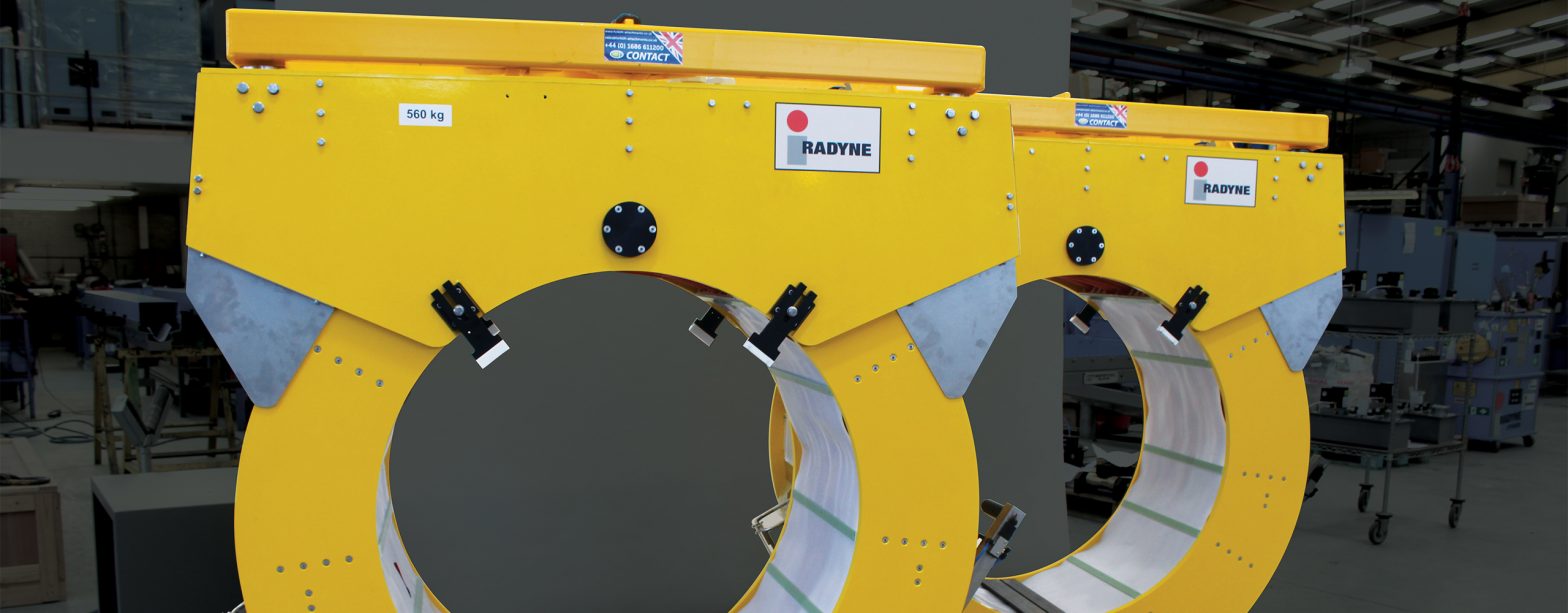

With Vertical and Horizontal operational capability and multiple coating heads the Radyne Merlin™ system provides a faster, more even coating. Standard coil modules combined with a PLC recipe system allowing for simple reconfiguration to accommodate multiple pipe sizes and field joint specifications.

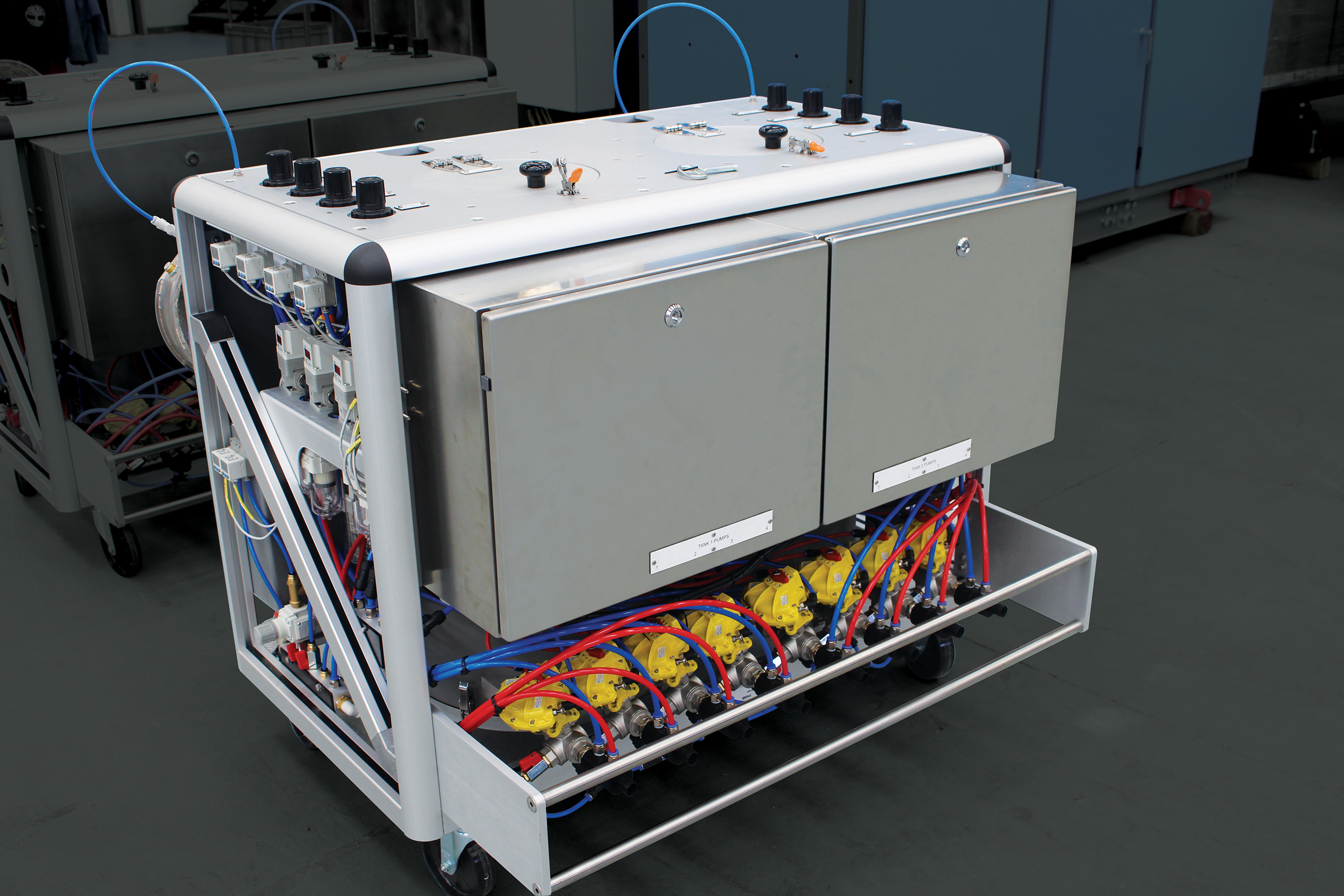

The coating process is controlled by the PLC using low temperature pyrometers to measure the surface temperature of the pipe for precise control. The integrated SCADA software records the system process parameters for use within your quality control system.

The Radyne Merlin™ comes in several standard machine sizes with interchangeable induction coils that covers the full range of pipe sizes.

Features

- Integrated induction coils in an easy automated open/close system

- Fully automated precision control and application of a two-coat FBE and co-polymer coating

- Multiple coating heads providing a faster, more even coating

- Vertical and horizontal operational capability

- Standard modular frames and assemblies allow for simple infield reconfiguration for multiple applications

Tech Specs

| Product Name | Size of Pipe | Number of Coils |

|---|---|---|

| 18" Merlin | 8" - 18" Pipe | 3 |

| 26" Merlin | 20" - 26" Pipe | 2 |

| 36" Merlin | 28" - 36" Pipe | 2 |

| 48" Merlin | 38" - 48" Pipe | 2 |

Bespoke sized units for specific projects can be designed at the request of customers

Literature

Literature