As the world’s focus shifts to the impacts of climate change and the environment, industry is taking note. Reactive measures are being put in place in almost every facet of human life and how we as a collective can curb the rate of climate change; from banning of use of fossil fuels to increased taxes on emissions. The metal forming industry is no exception with steps already being taken in an eco-friendly direction, but with many more steps until a ‘green industry’ can be established. Realistically, a ‘green industry’ relies on a multitude of factors that stretch far beyond, and can’t be easily influenced by, any given sector. This being said, small changes at the foundations can enact massive movement in the overall state of the environment.

This article sets out to highlight some of the key factors of environmental impact and ways they can be combatted within the scope of billet heating.

The Environment

The ferrous and non-ferrous metal sectors account for 8% of global greenhouse gas emissions, more than 4 times more than that of the aviation sector[1]. The leading factor causing climate change is the release of greenhouse gasses[2]. Greenhouse gasses are named as such owing to the greenhouse effect they cause. An insulating layer of these gasses such as Carbon Dioxide (CO2), Methane (CH4) etc. cause an excess build-up of heat in the atmosphere hence causing a sea-level rise through the melting of sea-ice.

It is said that by 2050, given the current rate of temperature rise, the earth will be 3°C hotter than pre-industrial levels. ‘The 2050 Scenario’ sets out that such a rise in temperatures would lead to approximately 3 meters of sea-level rise by 2100 – a rise that would see countries such as the Netherlands largely submerged[3]. A perhaps more alarming scenario is that of the ‘Hothouse Earth’. This hypothesises that if temperatures rise 2°C beyond pre-industrial levels, the effects are irreversible – there are no measures that can be taken to stop sea-level rise and irrevocable damage to ecosystems. This 2°C figure was therefore set as the baseline for the Paris Agreement[4].

Methods of Billet Heating

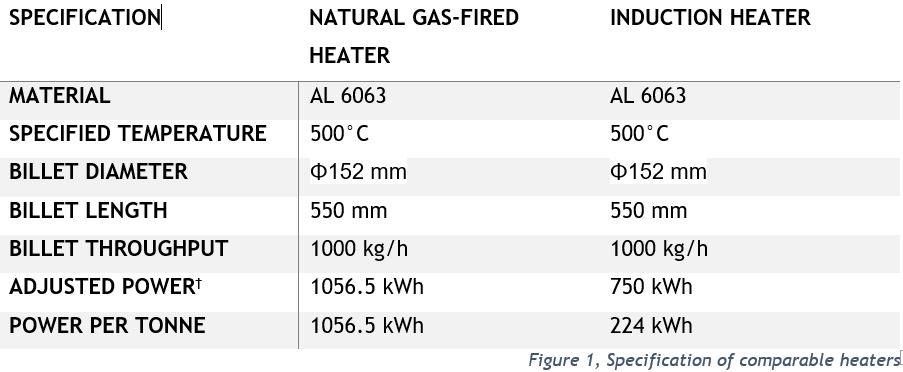

The heating of ferrous and non-ferrous billets is an energy-intensive process. Most commonly, billets are heated using either gas furnaces or through an induction heating process. Each method is industry proven over many decades of extrusion and each method has practical benefits. In order to feasibly make a comparison, one gas-fired heater and one induction heater both providing nominally similar temperatures and mass-throughput rates were selected.

† 1m3 Natural Gas is approximately 10.28kW assuming 100% efficient burn.

Gas & Induction

Historically, the use of gas-fired heaters are generally more commonplace in the industry. They tend to have marginally lower capital equipment costs and, depending on country of use, a lower running cost. As of 2020 Q3, the average cost per kWh of gas in the United Kingdom was £0.180. The average cost of electricity per kWh by the same metric is £0.810[5]. These lower running costs are seen as attractive in the short term. However, The Climate Change Committee estimates that these prices will change dramatically by 2030. Predictions suggest an increase of 100% in the price per kWh of natural gas by 2030, compared to a 42% rise per kWh of electricity in the large manufacturing sector[6] . This disparity is highlighted further in other European countries.

Gas furnaces require a period of preheating to achieve a set temperature before billets can be heated. This time is wholly dependent on the size of the furnace as well as suitable thermal insulation. For this reason, gas furnaces tend to be “powered on” at the desired temperature for long periods of time using energy regardless if billets are being heated or not. Alternatively, when utilising induction, energy is only expended when actively heating a billet and essentially no energy is used when a billet is not undergoing the heat process. This is sometimes seen as a more flexible method for operators of press lines, as supply of heated billets can be altered to match press throughput rates more easily without wasting energy.

A positive element of gas-fired heating is the simplistic design. This can allow for easier installation and operation by plant employees. This is often seen as a key benefit as to why a business may choose a gas-fired heater over a more technologically advanced alternative. As billets pass through the heater, they will homogenise at the set temperature throughout. This will take considerably longer than induction and can often cause scaling on the billet exterior, which can affect the final extrusion quality.

The biggest advantage of using induction is that it can allow for taper heating. Taper heating is utilised to achieve a gradient across the length of a billet – a key factor in reducing press die wear as well as offering isothermal extrusion at full press speeds. The design of gas furnaces incorporates a kiln lining that will need replacing periodically; this can lead to extended down-times on press lines. Similarly, induction coils will also need replacing, although this can take as little as thirty minutes. There have been advances in technology in recent years to the systems surrounding flue-gas recovery and CO2 flue scrubbers. These allow for a higher efficiency and lower emissions respectively.

Other Methods

Methods of billet heating are not limited to the two aforementioned processes. Magnetic heaters and the use of superconductors are starting to become effective in the sector. Both of these methods rely on electricity as opposed to fossil fuels to operate.

Environmental Impact

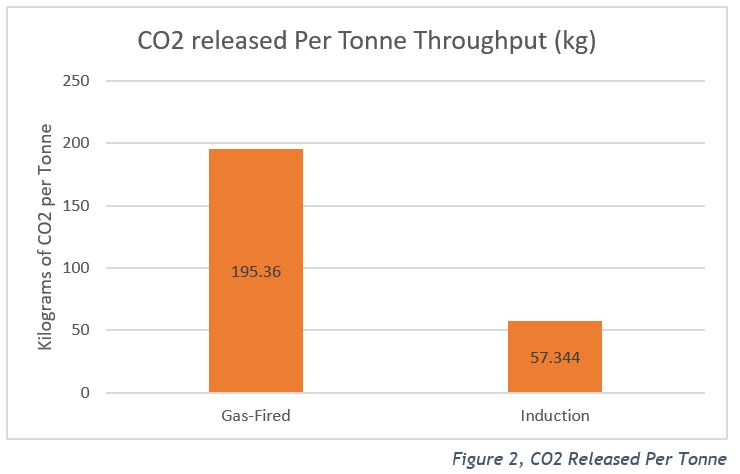

Both methods of billet heating discussed in the article will cause a detrimental environmental impact due to the release of greenhouse gasses. In the case of gas heating, the CO2 is released at the manufacturing facility. Induction relies entirely on each nation’s energy grid and therefore the local energy mix. Using Figure 1, it is possible to establish the potential CO2 emissions for each instance. The burning of natural gas releases 0.185 kg/kWh of CO2 while electricity production in the United Kingdom produces 0.256kg/kWh[7].

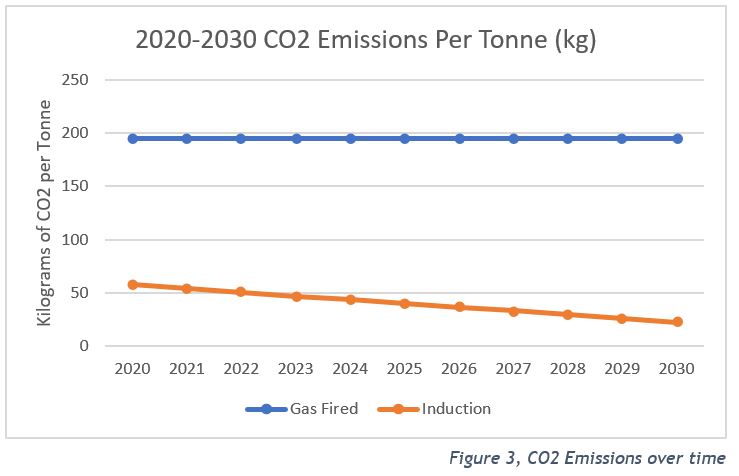

The large difference between the two methods is closely attributed to the ‘power on’ times of each system – induction only uses power on a per-billet basis. As the UK moves its focus towards renewable energy sources, the 0.256 kg/kWh CO2 emissions is expected to drop to 0.100kg/kWh by the year 2030[8].

As is shown in Figure 3, the expected CO2 emissions are set to drop under the UK’s ‘Net Zero by 2050’ climate approach.

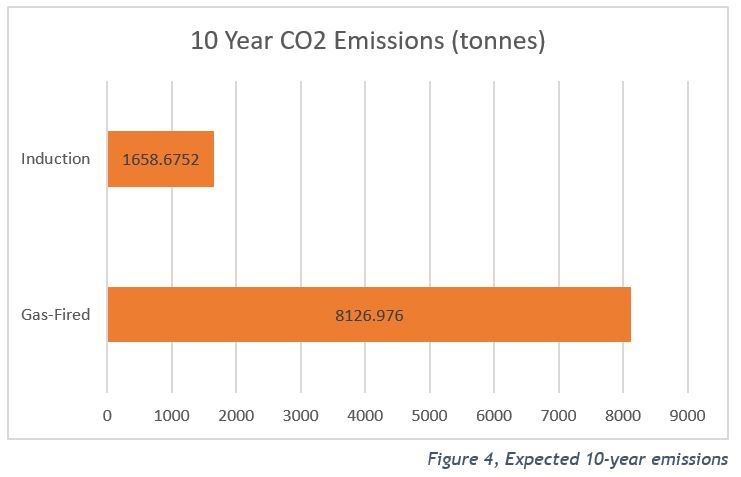

Using the values determined in Figures 2 and 3 it is possible to return an expected CO2 emission over a 10-year period.

The data in Figure 4 assumes 1000kg/h throughput, 16 hours a day, 5 days a week, 52 weeks per year. These values alone aren’t especially quantifiable from one’s personal perspective. It can be more easily visualised as follows. A fully-laden Boeing 747-400 emits approximately 90 kg/h of CO2 per hour of flight per passenger[9]. The 10-year plant emissions from a relatively small gas-fired billet heater as specified in Figure 1 are approximately the same as flying a Boeing 747 from Heathrow to JFK – 34 times. Or driving an Aston Martin DB9 to the moon and back – 27 times.

This level of environmental impact is not sustainable.

The Future

The ferrous and non-ferrous extrusion market is expanding. Current figures estimate a compound annual growth rate (CAGR) of 3.8% between 2021 – 2027[10] for aluminium extrusion. This predicted CAGR would see a market revenue forecast increase from $57.3 billion to $91.67 billion by 2027. This is inevitably going to cause and greater and greater impact to the environment as the sector expands.

The UK government has recently rolled out an initiative to large industry offering grants that will help increase energy efficiency and lower carbon-footprint. Phase 1 is providing up to £40 million for “projects deploying technologies that improve the energy efficiency of industrial processes” & “feasibility and engineering studies into energy efficiency and deep decarbonisation measures for industrial processes”[11]. Other countries, such as Norway, have recently invoked a price increase per tonne of CO2 emitted four-fold[12]. Further development into flue-gas recovery and CO2 scrubbers for gas-fired furnaces are helping to increase efficiency and reduce CO2 emissions.

Reactive measures are what we as a society have relied on, but it’s no more than a sticking plaster. We need to turn reactive into proactive. Actively making changes that are better for the environment. On an individual basis it’s easy to remove oneself from the decisions being made with regard to the environment. We can take the easier or cheaper option because it’s exactly that, easier and cheaper. What isn’t as easy to stomach is the damage that we have, do, and will cause our planet. But changes can be made to halt this harm. Humanity faces a climate crisis. It can be stopped.

Thomas Postins, B.Eng.

Sales Manager Banyard – Inductotherm Heating and Welding

For further information on induction billet heating products click the link here.