Ferrites

Tube and pipe producers worldwide recognise the production benefits and cost savings that can be achieved from the use of correctly designed impedors that take full advantage of the very latest developments in ferrites material technology.

Modern tube mills that operate at higher line speeds have created demand for impedors that deliver superior performance. Such enhanced performance can only be achieved by using the very best ferrites available.

Inductotherm Heating and Welding, in recognition of the above, has developed ferrite material that possesses higher magnetic permeability whilst offering the highest Curie temperature (330ºC), minimal core loss and high saturation flux density over a wide operating temperature range. These are just some of the reasons why a growing number of tube and pipe producers worldwide choose Thermatool ferrites in order to optimise the performance of their mills. Thermatool offers four different types of ferrites which can be cut to length, if required.

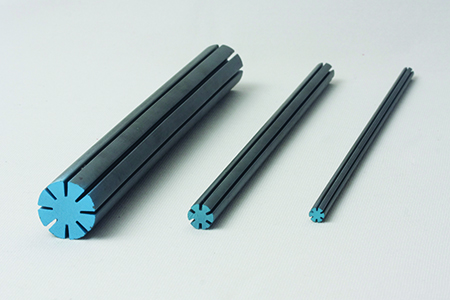

Fluted Ferrite (FF)

The best all round ferrite offering a large mass of material with maximum cooling capacity due to its “fluted” design.

This type is ideal for use with through flow impedors.

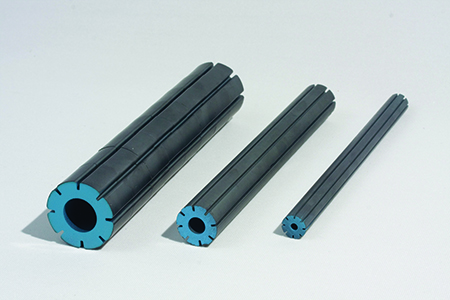

Fluted Hollow Ferrite (FHF)

The hollow centre permits this type of ferrite to be utilised where a mandrel is used or for return flow impedor applications.

This type is ideal for use with return flow impedors

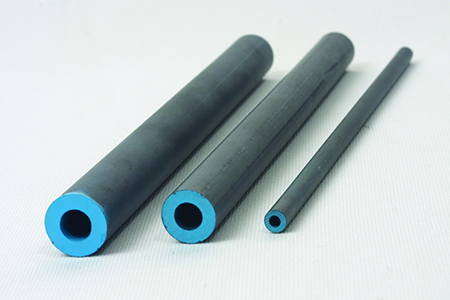

Hollow Ferrite (HF)

This type of ferrite can be utilised where high numbers of ferrite rods are required, particularly where extra cooling capacity is needed.

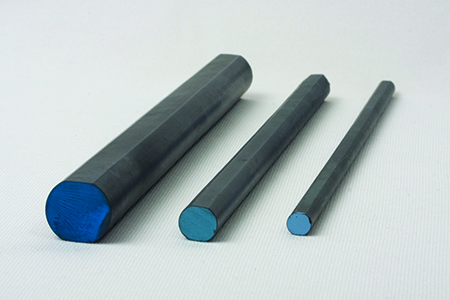

Flat Sided Ferrite (FSF)

Commonly used in larger impedors where high numbers of ferrite rods are required, thus reducing overall cost, however, cooling is not as efficient as that which can be achieved using fluted ferrites.

For more information about Inductotherm Heating & Welding’s line of consumable products, please contact us or your local Sales Representative, or call our Customer Support on +44 (0) 1256 335 533 or use the request information form below.